Homepage » Strip Processing Technologies » key technologies » Ovens and cooling section with floatation technology

REDEX Group is specialized in heating, cooling or quenching strips in continuous processes.

This temperature increase, stabilization and going down are necessary in strip coating or heat treatments.

We develop processes minimizing energy consumption (Gaz or electric solution available) according to the chemical product to be applied and the kind of strip to be coated for drying and sintering of the coating.

We also provide all kinds of continuous heat treatment for Aluminum with taking care of energy or water consumption. We manage the treatment of the exhaust systems according to each country’s regulations. Our equipment is simple to maintain because access is large enough for easy access to the main components.

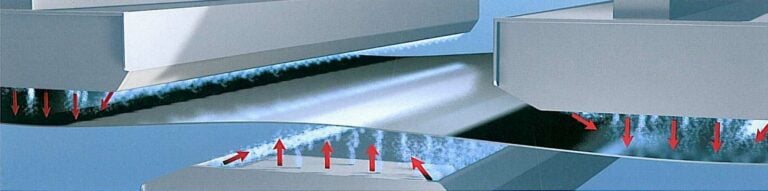

Strip is transported or floating through the ovens without being in contact with any components on a cushion of heated air or cooling air provided by a eco energy recirculation system which is designed with jet air nozzles installed on top and bottom of the ovens.

Strip floatation is controlled with a patented solution which consist of non-contact strip position control devices which control the position of the strip in the movement plane and transversely to the strip movement direction with one linear motor, wherein the temperature control has at least one heating section on the inlet side and a cooling side on the outlet side.

Heat exchanges and the load capacities of each section are designed upon customer requests and can achieve one of the best throughput of the market.

Water or air quenching are also available for aluminum strips heat treatment.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.

REDEX Group is a European Engineering company offering Mechatronics solutions worldwide.